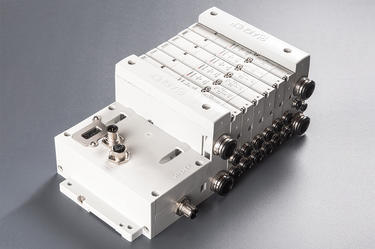

When it comes to pneumatic valves, Arabian Automation stands out as one of the premier manufacturers and suppliers in the UAE. With a dedicated focus on delivering high-quality pneumatic valves, we have established ourselves as a trusted name in the industry. Our extensive product range includes a variety of pneumatic valves designed to meet diverse industrial needs. From solenoid valves to control valves, our offerings are engineered for precision and reliability.

At Arabian Automation, we take pride in our commitment to quality and excellence. Our pneumatic valves are manufactured to stringent standards, ensuring optimal performance and durability in various applications. Whether you require valves for automation systems, manufacturing processes, or other industrial uses, we have the right solutions for you.

As a leading pneumatic valves manufacturer and supplier in the UAE, we understand the importance of seamless integration and compatibility. Our team of experts is dedicated to providing comprehensive support, from product selection to installation, to ensure that our clients receive the best value and performance from our pneumatic valves.

When you choose Arabian Automation as your pneumatic valve partner, you can be confident in our expertise and commitment to delivering top-notch products and services. Contact us today to learn more about our pneumatic valve offerings and how we can assist you in meeting your industrial needs. Trust Arabian Automation for all your pneumatic valve requirements in the UAE.

Pneumatic systems rely on a variety of valve types to control the flow of compressed air for various applications. Here’s a brief overview of some key pneumatic valve types:

Solenoid valves are electromechanical devices that use an electromagnetic coil to control the flow of compressed air. They are commonly used for automation and remote control applications, allowing precise on/off control of airflow.

Namur valves are a specific type of solenoid valve designed to meet the Namur standard. They are often used in industrial automation to control pneumatic actuators in a standardized manner, providing flexibility and ease of integration.

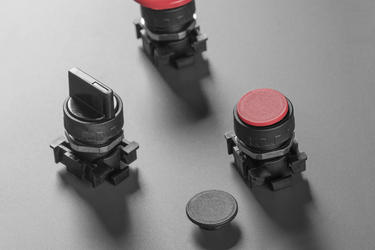

Rotary hand lever valves are manual valves that feature a rotating lever for control. These valves are typically used when operators need to manually control airflow by turning the lever to open or close the valve.

Pedal valves are foot-operated valves commonly used in applications where hands-free control is necessary, such as in medical equipment, industrial machinery, or safety systems. Pressing the pedal activates or releases airflow.

Panel valves are designed for easy mounting on control panels. They are compact and space-efficient, making them suitable for applications with limited installation space. Panel valves provide reliable control in various industrial settings.

VDMA 18mm valves conform to the VDMA (Verband Deutscher Maschinen- und Anlagenbau) standard and are often used in European industrial automation systems. They are known for their robust design and compatibility with VDMA cylinder interfaces, ensuring seamless integration into pneumatic systems.

Each of these pneumatic valve types serves specific purposes within pneumatic systems, offering versatility and control for a wide range of applications across industries. The choice of valve type depends on factors such as system requirements, automation needs, and the desired level of manual or automatic control.

A pneumatic valve is a mechanical device used to control the flow of compressed air in pneumatic systems. It regulates the direction, rate, and amount of airflow to various pneumatic components, such as cylinders and actuators.

Solenoid valves use an electromagnetic coil to actuate a movable plunger or spool, which controls the flow of air when the coil is energized or de-energized. They are commonly used for remote and automated control.

A Namur valve is a type of solenoid valve designed to meet the Namur standard. It’s commonly used in industrial automation to control pneumatic actuators in a standardized way, facilitating integration into automated systems.

Manual rotary hand lever valves are used when operators need to manually control airflow by turning a lever. They are convenient for applications where hands-on control is essential, such as in emergencies or for adjusting settings.

Pedal valves are foot-operated valves often used in applications where hands-free control is necessary, such as in medical equipment, safety systems, or industrial machinery.

Panel valves are compact valves designed for easy mounting on control panels. They are space-efficient and ideal for applications with limited installation space, offering reliable control in various industrial settings.

VDMA 18mm valves conform to the VDMA standard and are commonly used in European industrial automation systems. They are known for their robust design and compatibility with VDMA cylinder interfaces, ensuring seamless integration into pneumatic systems.

Choosing the right pneumatic valve depends on factors such as the application requirements, the type of control needed (manual or automated), and the specific functions the valve must perform. Consulting with pneumatic system experts can help ensure the correct valve selection.

Regular maintenance includes checking for leaks, cleaning valves, inspecting seals, and replacing worn-out parts as needed. Proper maintenance ensures the longevity and reliability of pneumatic valves.

HAVE A QUESTIONS? CALL US

+971563250325

GIVE FEEDBACK THROUGH EMAIL

sales@arabianautomationuae.com